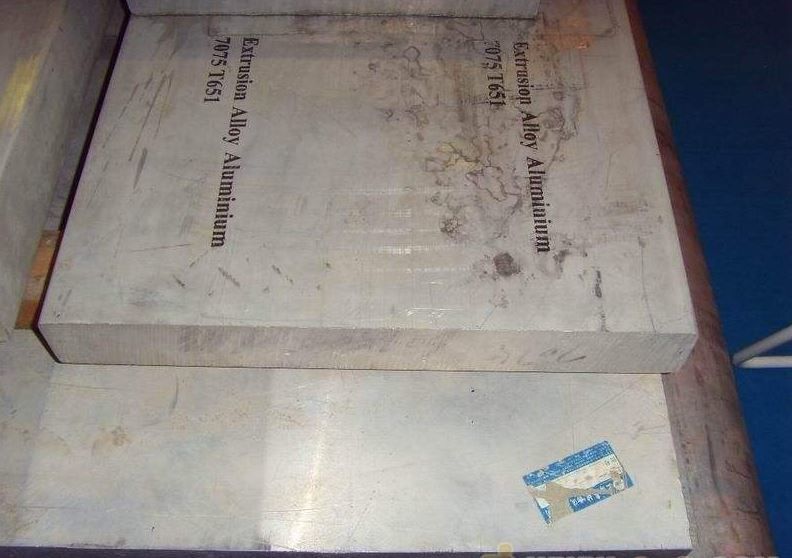

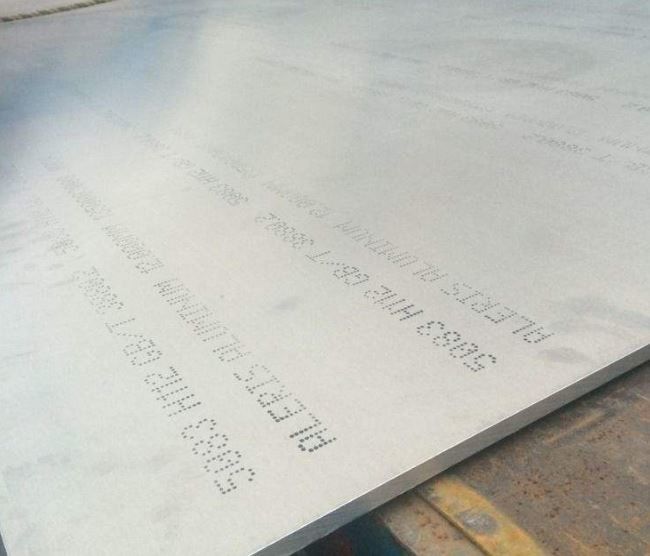

Tensile Strength 525Mpa High Strength 7075 T651 Aluminum Sheet Plate

Introduction

7075 aluminum plate belongs to the Al-Zn-Mg-Cu super-duralumin, 7075 alloy is an ultra-high-strength deformed aluminum alloy that has been used in the aircraft industry in the late 1940s and is still widely used in the aviation industry.

It is characterized by good plasticity after solution treatment, particularly good heat treatment strengthening effect, high strength below 150 ℃, and particularly good low temperature strength; poor welding performance; stress corrosion cracking tendency; aluminum or other Protection processing use.

Two-stage aging can improve the alloy's ability to resist stress corrosion cracking. The plasticity in the annealed and just-quenched state is slightly lower than 2A12 in the same state. It is slightly better than 7A04. The static fatigue of the sheet is sensitive to notches, and the stress corrosion performance is better than 7A04. Among them, the 7075-T651 state is particularly top-grade and is known as aluminum The most excellent product among alloys has high strength, far better than mild steel. This alloy has good mechanical properties and anode reaction, and is a typical aerospace and military special aluminum alloy material.

Chemical Composition

| 7075 Alloy Chemical Composition Limits |

| Weight% |

Al |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Other Each |

Others Total |

| 7075 min |

Rem |

- |

- |

1.2 |

- |

2.1 |

0.18 |

5.1 |

- |

- |

- |

| 7075 max |

Rem |

0.40 |

0.50 |

2.0 |

0.30 |

2.9 |

0.28 |

6.1 |

0.20 |

0.05 |

0.15 |

7075 Aluminum Sheet Plate Typical Mechanical Properties

| Material |

Temper |

Thickness (in) |

Tensile Strength (ksi) |

Yield Strength (ksi) |

Elongation % |

| Alloy 7075 Sheet |

T6 Bare |

0.125 - 0.25 |

78 |

69 |

8 |

| Alloy 7075 Sheet |

T651 Bare |

0.25 - 0.50 |

78 |

67 |

9 |

| Alloy 7075 Sheet |

T651 Bare |

0.5 - 1.0 |

78 |

68 |

7 |

| Alloy 7075 Sheet |

T6 Clad |

0.188 - 0.25 |

75 |

64 |

8 |

| Alloy 7075 Sheet |

T651 Clad |

0.25 - 0.50 |

75 |

65 |

9 |

| Alloy 7075 Sheet |

T651 Clad |

0.5 - 1.00 |

78 |

68 |

7 |

7075 Aluminum Typical Physical Properties

| Characteristic |

English |

Metric |

| Nominal Density (68° F / 20°C) |

0.101 lbs./ in ³ |

2.80 Mg/m³ |

| Melting Range |

990° F - 1175° F |

532°C - 635 °C |

| Specific Heat (212 °F / 100°C |

0.23 BTU/lb - °F |

960 J/kg-°K

|

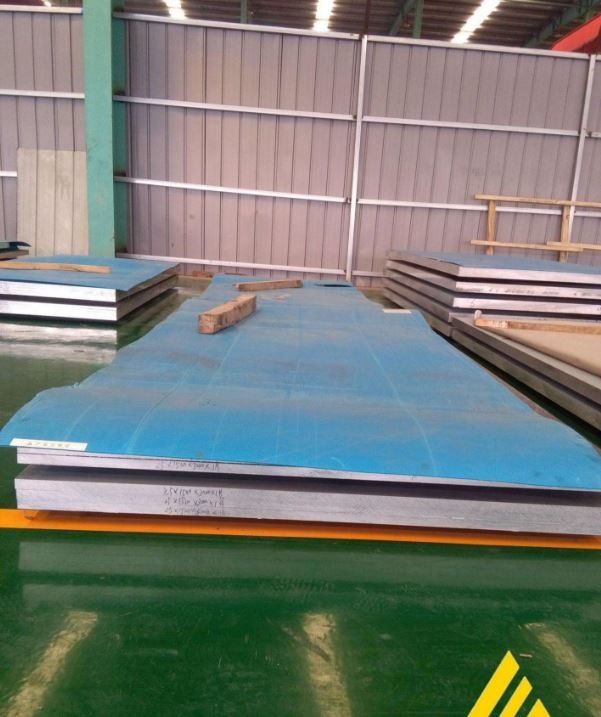

7075 Aluminum Alloy Typical Applications

7075 status: O, T6, T73, T76 plates.

7075 state: O, T651, T7351, T7651 thick material

7075 state: O, T6, T173 stretch tube

7075 status: O, T6, T6510, T6511, T73, T73510, T73511, T76, T76510, T76511 Extruded tube, shape, rod, wire

7075 state: O, H13, T6, T651, T73, T7351 rolled or cold worked bars

7075 status: O, H13, T6, T73 cold processed wire

7075 status: T6, T73 rivet wire

7075 status: F, T6, T652, T73, T7352 forgings

7075 typical use

Used to manufacture aircraft structures and other high-stress structural parts that require high strength and strong corrosion resistance, such as aircraft upper and lower wing panels, stringers, bulkheads, etc. After solution treatment, the plasticity is good, and the heat treatment strengthening effect is particularly good. It has high strength below 150℃, and has particularly good low temperature strength, poor welding performance, and stress corrosion cracking tendency. Two-stage aging can improve the SCC resistance. Provided by Wuxi Hanshin Metallurgy.

species:

Common types of aluminum plates and aluminum alloys are: aluminum strip, aluminum foil, aluminum plate, aluminum tube, mirror aluminum plate, alloy aluminum plate, curtain wall aluminum plate, pattern aluminum plate, embossed aluminum plate, aluminum rod, non-slip aluminum plate, aluminum plate, cold rolled aluminum plate, hot rolled aluminum plate , Southwest plate (import) mirror aluminum plate, pure aluminum plate, pure aluminum coil, deep drawn aluminum plate, lighting aluminum plate, bottle cap material, circuit board, transformer special aluminum strip, aluminum foil, composite bottom plate, rust-proof aluminum plate, etc.

Features

7075 is an aluminum alloy with zinc as the main alloying element, but sometimes a small amount of magnesium and copper are added. Among them, the super-hard aluminum alloy contains zinc, lead, magnesium and copper alloys, which are close to the hardness of steel. It can be strengthened by heat treatment. It is a high-strength, heat-treatable alloy with ordinary corrosion resistance and good mechanical properties. Aluminum 7075 is a cold-treated forging alloy with high strength, far better than mild steel. 7075 aluminum alloy is one of the most powerful alloys commercially available. Ordinary corrosion resistance, good mechanical properties and anode reaction. The small grains make the deep drilling performance better, the tool wear resistance is enhanced, and the thread rolling is more different.

Sample size: bar diameter (diameter of square bar, hexagonal bar inscribed circle) ≤ 25

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!